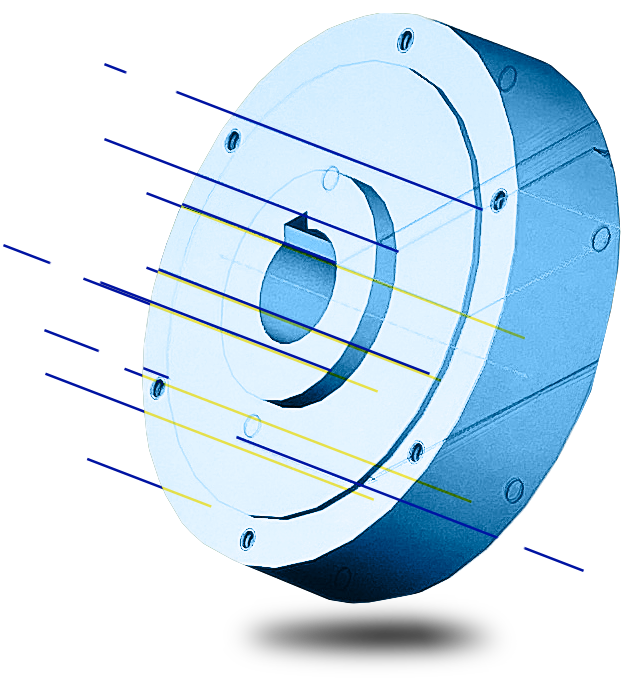

Behind the machines: Clever Sleeve Application machinery.

Partner Focus: How the power of 3D Design Shapes Every Clever Machine

Every Clever sleeve applicator starts long before the first part is made; each applicator is the result of an intensive, complex and strategic process utilising 3D visualisation as the starting point to design, develop and manufacture every machine.

This approach enables us to test every detail before production begins, helping us build machines that perform well, last longer and meet our customers’ needs more precisely.

The Design Journey

Designing a sleeve applicator is more than just fitting parts together. It’s about anticipating challenges, optimising performance, and engineering solutions before they even exist in the real world.

Here’s how 3D design transforms that process

1️⃣ Brief Analysis & Technical Requirements

Each project starts by analysing the customer's container format, performance goals, speed, available floor space and any specific line requirements.

2️⃣ Parametric Modelling & Simulation

Our engineers create detailed 3D models and simulate real operating conditions like loads, movements, and spatial constraints. This allows us to evaluate behaviour and detect potential issues before physical prototyping, saving time, cost and ensuring precision.

3️⃣ Iteration & Optimisation

The design process is continually improving. It evolves through multiple revisions, integrating customer feedback and performance insights to enhance efficiency, reliability, and operator experience before the first machine is even built.

4️⃣ In-House Prototyping & Validation

Once the digital model is finalised, we generate precise technical drawings, parts lists, machining data, and mechanical/electrical interfaces. These are validated by comparing digital designs against real-world assemblies to ensure every element performs exactly as intended.

What is the main challenge in the 3D design of sleeve applicator machines?

Bringing mechanical, electrical, and spatial requirements together into one cohesive model that anticipates every possible limitation.

With 3D design, we can literally “see the invisible” — spotting potential conflicts or inefficiencies long before production begins. This level of foresight ensures every Clever machine delivers seamless performance, maximum uptime, and simplified maintenance once installed.

For customers, this process translates directly into value:

Faster lead times

Greater reliability

Tailored machine integration

Consistent, efficient production

Our Sleeving Partner: Clever Machines

Watershed Packaging and Clever Machines SRL, a global leader in shrink sleeve application machinery, have built a strong relationship since their partnership began over 10 years ago.

Together, we work hard to deliver flexible, reliable, and sustainable sleeving solutions for businesses of all sizes.